Everything You Need To Know About 4 Types Of Clothing Manufacturer

Are you in the first step of creating your clothing brand? And you are wondering which types of clothing manufacturers will suit your business. In this article, we explain the types of clothing manufacturers and the difference between them. Read on and follow up on advice from the team of fashion experts and consultants with in-depth knowledge.

[toc]

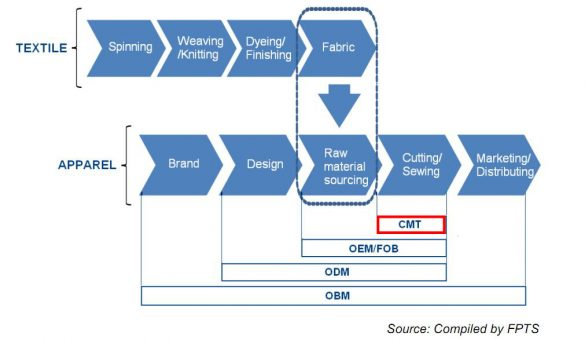

Cut, Make, Trim (CMT) Manufacturer

What is CMT?

CMT is the abbreviation for Cut, Make, Trim. When you know exactly how you want your outfits to look, this method of garment manufacturing is ideal. That is, you have determined the concept, size, classification, patterns, textiles, color, design, and printing.

A clothes maker just performs three things: cut, make, and trim. Automatic fabric cutters, expert sewing, and quality control and quality control professionals are all desirable features of a clothing manufacturer that provides this service.

CUT

The cut is a very precise first step where economies of scale exist. For the sake of efficiency, you can imagine that we do not cut the shirts one by one, but that we try to bring them together by the model to cut all the fabric parts at the same time.

Before tackling the cutting, it is important to know what the exact needs of this production are. In other words, always double-check the measurements, the quantities per size, as well as the measurement of each piece that will make up the shirt. This step to avoid waste of fabric and money on a large order.

MAKE

After the fabric has been cut and adjusted, the cut pieces go through our customization workshops. The different parts that make up the garment are then cut from the fabric and then assembled during different manufacturing steps.

Before carrying out the manufacturing workshops, always have tested by launching “preproduction” to verify that each model will be correctly assembled.

The versatile collaborators then assemble the parts to achieve the final product. This includes making the buttonholes, fitting the buttons, and all the operations involved in making clothing take shape

TRIM

The trimming process is the last step of this clothing manufacturing process. It is also at this phase that a final quality check for your finished clothing. The finishing touches are applied, and the fabric is perfectly finished.

So, let’s take a look at all information you have to provides to the CMT apparel manufacturer:

Details about the design, including seam-to-seam measures

- Fabric evaluation and selection

- Fabrics patterns

- Stitching techniques

- Selection of haberdashery

- Methods of printing (if necessary)

- Embroidery techniques (if necessary)

- Methods of packing

When you know exactly what you expect and know how to make your clothing brand stand out, this type of clothing manufacturer is perfect.

Advantages of CMT

CMT is a more environmentally friendly alternative since it allows for more control over waste and the utilization of renewable resources. It is suitable for small businesses or startups.

In addition, because you select the fabric yourself with CMT, you are not limited by minimums quantity, giving you more options, greater quantity flexibility, and cost savings.

Disadvantages of CMT

Although this system is ideal for small enterprises and startups, it is not suitable for everyone. There are a few disadvantages as well.

It’s impossible to predict when garment production may be delayed. Materials that have become detained in customs, and labels that have been produced erroneously or wrong delivery address are the most common things.

Moreover, using a CMT to manufacture is usually the more expensive choice. It all adds up because you’ve paid for the textile, designs, shipment, import tariffs, and taxes.

CMT will have to outsource fabric dyeing, stitching, embroidery, and/or specialized labels, which will increase the cost and time. About custom trims, minimum order quantities are usually very high.

Original Equipment Manufacturer (OEM)

What is OEM?

An OEM product is originally manufactured to the buyer’s specifications. All products with pre-selected sizes, colors, materials, functions, and designs are considered OEM products. Some view these products as purely buyer-based, and others as original but modified factory designs, no matter how minor the modifications.

With OEM manufacturers, the company only needs to hire an outsource company to help them process, design, assemble and manufacture clothes. The OEM company’s production line can produce products for many different parties, thereby helping to optimize resources, costs, time,… for both customers and OEM companies. This is a win-win relationship.

Advantages of OEM

OEM companies are gaining popularity among multinationals and startups. This business is very profitable because they can save a lot of money on bulk orders.

In addition, you can find high-quality clothing products of all kinds at low prices. All products are carefully checked by the manufacturers.

Disadvantages of OEM

Product perfection is the foundation of the OEM industry. The majority of companies outsourcing production to OEMs demand a certain quality. You will then find fewer OEM suppliers in the markets offering a much higher than average quality. In contrast, the majority of these suppliers provide samples to buyers before signing mass production agreements.

The majority of OEM companies work for large orders, so you need to make large quantities, this means having a steady stream of customers to procure OEM services.

Original Design Manufacturer (ODM)

What is ODM?

An original design manufacture product is based on the design of a manufacturer, this product can be the result of the research and development work of a supplier or a counterfeit product of another brand. You can put your logo on ODM clothing.

Besides, ODM companies produce the kind of products you want. However, they are only changed slightly. However, these kinds of suppliers benefit buyers because it is not always essential to design products and invest a lot of time in research and development.

You can take into the expertise of ODM companies that offer bulk product manufacturing for small businesses. There are two types of categories in the manufacture of ODM, the private label on one side and the white label on the other.

Private label products are finished products that are sold to particular retailers. In addition, white label products are said to be generic and are sold to all kinds of retailers who will resell them under different brands.

Advantages of ODM

ODM production has an important advantage because it saves time and money by not having to design products and deal with R&D. By collaborating with ODM providers, you will be able to think about how to grow your business with their products. These suppliers often produce prototypes.

Suppliers also offer cheaper products and since product design is not necessary, ODM may be preferable to OEM in some cases. Both are advantageous depending on what you are looking for first, price competitiveness or non-price competitiveness.

The ODM process saves time, purchasing finished products. If you are using OEM companies, you have to do product design and sourcing reliable suppliers which are very time-consuming. So by buying finished products rather than parts, you will sell your products faster and have more time to improve your branding and your marketing system.

Disadvantages of ODM

First of all, ODM manufacturers make and sell the same kind of products to several other companies, so it is difficult to stand out unless you choose a single supplier. Moreover, it is difficult to change supplier because the design belongs to them

Second, these suppliers do not offer a wide variety of products. So if you want to sell products with specific characteristics you had better look to an OEM supplier. ODM suppliers may allow you to customize your products for wholesale orders but these will only be slight modifications.

Private Label Clothing Manufacturer

What is PLC?

A private label clothing is a product designed by a manufacturer, which is then taken up and redistributed by the brands, which market the product under their own identity. These brand will be able to buy “ready-made” products from a manufacturer’s catalog and then offer it is to their customers

These clothing products are often generic, easy-to-match styles that can be easily modified with brand logos and tags. During the manufacturing process, your brand label is added and the items become part of your company brand.

For example, a manufacturer produces a floral dress that it makes available in its catalog; several companies can access to buy this dress from that factory. These companies will then market this same dress under different brands and all they need to do is only change the label. 1 dress, 100 brands, 100 different prices.

Advantages of PLC

With the private label, you won’t have to worry about producing the product you want to sell. There is already a producer who will take care of this. All you have to do is go buy this product and then brand it using the private label concept.

Private label allows you to create the products you want without requiring a large budget. Moreover, you got benefits from expertise with low minimums, quick production introductions, and no research and development costs.

Disadvantages of PLC

You must ensure the quality of the products that you will put your logo on. If anything goes wrong, you can’t blame the manufacturer. Finally, think about any legal obligations you may face. Trading rules, trademarks, and patents are all complex worlds in which you do not want to get involved. Even words are susceptible to copyright, so tread carefully if you’re in the shadow of a larger brand.

Which types of clothing manufacturing are good for your business?

Compare ODM vs OEM

So OEM vs ODM, which method is best for your business? The table below can give you some information to compare.

| Factors | OEM | ODM |

| Unit price | No difference | No difference |

| Injection molds and tools | Paid by buyer | Paid by the supplier |

| Product development time | 1 to 6 months | 1 to 4 weeks |

| Serial production time | No difference | No difference |

| Product data sheet | Provided by the buyer | Reverse engineering by the purchaser or provided by the supplier. |

| Product conformity | No difference | No difference |

| Ownership of intellectual property | Intellectual property owned by the buyer | Intellectual property owned by the supplier |

| Benefits | The suppliers take all responsibility, so the buyer does not have to do anything. It is possible to freely customize its products You own the intellectual property | The product development cycle is shorter. Only certain details can be adjusted or customized. You are not responsible for the components or manufacturing. |

| Disadvantages | You must handle the materials and your design. Creating a new design can take many months | The choice of product is limited, you only get what the clothing manufacturer offers. Reverse engineering a specification is complicated and time consuming. Sometimes it can take less time to fully design an OEM product. The same products are or will be sold by many other competitive companies. You do not own the intellectual property and you risk litigation with other companies. |

Working with an OEM clothing manufacturer is the best option when you require entirely tailored garments from an apparel factory. You won’t need white-label or private-label providers if you know how to make your brand stand out. You’ll work with factories that create clothing based on your specifications.

OEM products are suitable for startups because it is difficult for them to manufacture products. In addition, due to globalization, OEM projects benefit the majority of small and medium industries.

And the ODM production is perfect if you know how to build your brand from a marketing and PR perspective but do not have so much knowledge from a technical standpoint. You also know how to design your unique clothing.

Compare CMT vs PLC

In deciding between CMT and PLC products, there are several aspects to consider when deciding between these two manufacturing processes. When choosing CMT production, you have complete control over everything. Manufacturers only perform cutting, Making, and Trimming processes.

The PLC manufacturer is responsible for the entire process, from design to delivery to the point of Freight on Board (FOB). They provide all services such as design assistance, pattern making, grading, sourcing fabrics and components, sample, bulk production, packing, and freight forwarding. All you have to do is confirm the sample and agreement.

A private label clothing manufacturer is the ideal choice for anyone unsure about the technical elements of their clothing line. A clothes factory like this will provide you a variety of ready-to-wear options. All that’s left for you to do now is select your eye-catching logo for your brand.